Warehouse automation is about uncovering repetitive tasks and streamlining warehouse processes with minimal human assistance via the use of software and digital technologies. Traditionally, IT advancements in warehousing applications have been limited to conveyor picking, palletizing/depalletizing, or other highly repetitive tasks. In response to changing operational environments, logistics and warehouse businesses worldwide are automating warehouses.

Legacy warehousing systems are faced with a multitude of challenges, and many can be mitigated using automation. Let’s take a closer look-

Poor Inventory management: With the rising need for faster throughput, it is in the best interest of warehouse companies to keep inventory moving in and out frequently. The longer an item sits on a shelf, the less viable it becomes, and the need to offer a promotion or discount becomes unavoidable

Disordered workflows: The warehouses perform multiple operations, and each operation is tied together to workflows. The accidental redundancies in warehouse workflows increase labor costs and consume the productive bandwidth of executives.

Unsatisfactory order management: Order management comprises processes from accepting the order to picking, packing, shipping, and handling post-sales including refunds and returns. The absence of automation may result in errors in any of these processes resulting in the collapse of the entire workflow

Improper labor management: Warehouse managers continuously strive to achieve high productivity, at the same time minimize labour costs. Labor costs can constitute about 65% of the total warehouse budget. Managing them with effective forecasting tools can improve the overall warehouse process productivity

Substandard data management: Today, warehouses generate heaps of data due to the execution of multiple processes. This data can be too large to manage and analyze manually, it holds valuable insights for making the warehouse processes more efficient.

However, advancements in technologies and the expansion of e-commerce have created opportunities for more and more automated solutions in wider applications, including warehousing and distribution center activities. Now a large part of logistics companies’ success lies in the ability to create efficient supply chains and cut operations costs and related expenses. The automated warehouse management system (WMS) covers the most important warehouse operations including inventory tracking, labor management, back-office management, order picking, fulfillment, etc. In context to the maturity of automation in warehouse, 4 levels can be briefly outlined below-

| Warehouse automation Maturity Layers | Technologies used |

| Low automation | Basic inventory recording systems, Scanners, Specific applications |

| System automation | Voice-directed technologies, Mobile radio frequency, pick-to-light systems |

| Mechanized automation | Conveyors, Automated Storage and Retrieval System (AR/RS) |

| Advanced automation | Automatic sorters, Automated guided vehicles (AGVs), Robotic picking system, Automatic palletizer |

Looking ahead, we estimate continued growth in warehouse automation systems driven by the three massive secular tailwinds of automation technologies, e-commerce, and logistics outsourcing.

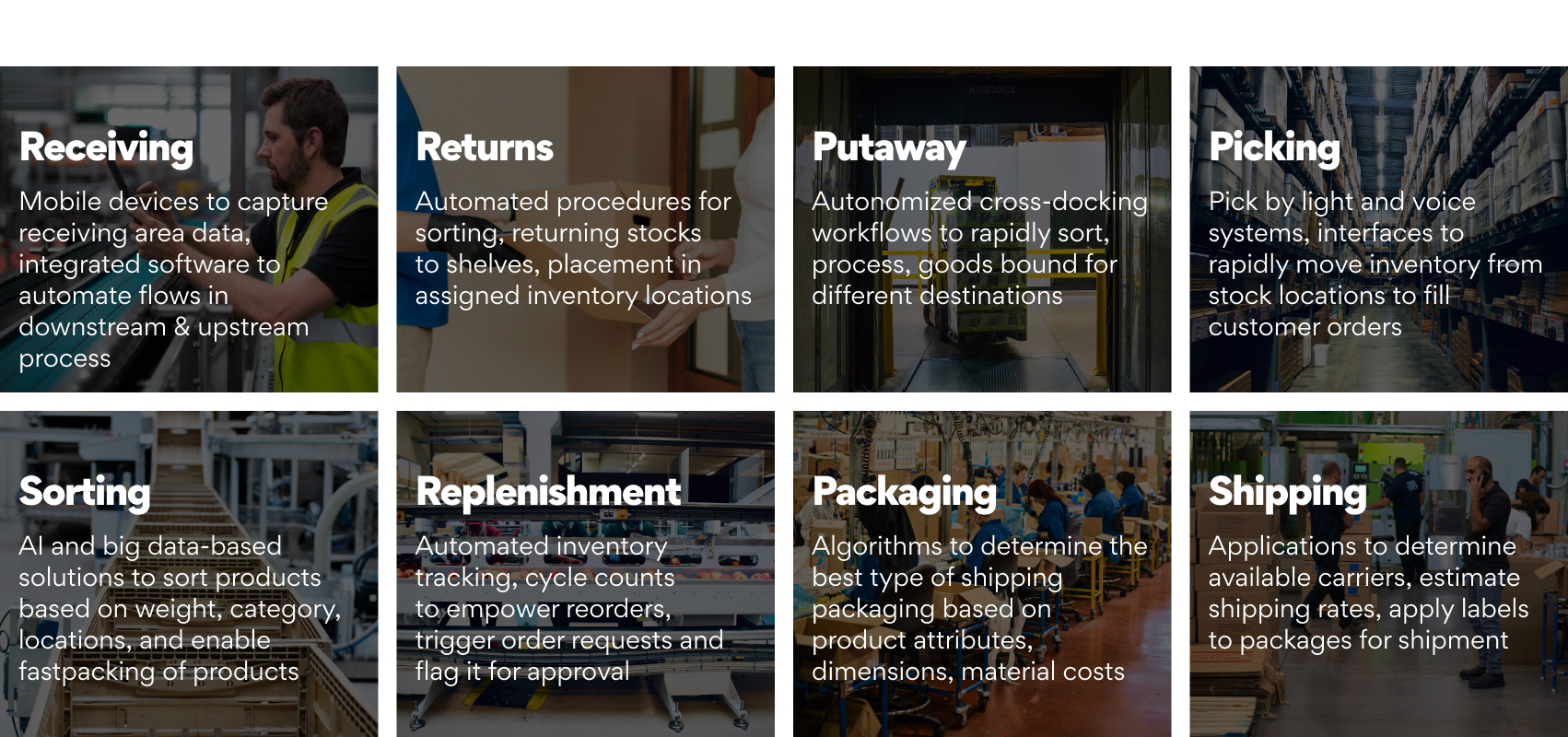

Our warehouse automation offerings intend to guarantee the enterprise-strategic operations of Logistics companies aligned to the needs of their customers. Refer to our suite of warehouse management offerings below-

The right level of digital technologies and autonomy will enable faster, safer, and more efficient end-to-end warehouse operations. Let’s see how warehouse automation impacts various processes –

Our strategy pivots on integrating people, processes, and systems to the right degree. We build digital architecture for end-to-end connectivity by integrating various technologies. Our capabilities in Low/ No-code customizations, seamless WMS integrations, Data, Performance analytics, and real-time reports supercharge warehouse performance and productivity and minimize human errors.

Implementing our automation solutions accelerate warehouse processes and present core benefits to logistics companies. The benefits as listed below –

Boost productivity and efficiency: Warehouse management systems coupled with advanced technologies like Data analytics platforms, ML, and big data enable logistics organizations to accelerate order fulfillment and inventory accounting. The systems improve efficiency by streamlining operations, cutting the ‘grey time’ spent manually completing by admin thus increasing the proportion of each shift spent as productive time

Inventory optimization: By minimizing human interventions, our automation offerings contribute to optimized control in inventory, in turn allowing for precise inventory counts and inventory data. The technologies help manage inventory, distribute goods, reduce labor requirements, and speed up processes

Strengthened safety: The Warehouse Management software provides real-time inventory tracking and management. Workers have access to all necessary data that helps them pre-order or know the exact location of the product. The automation and tracking ensure workload safety and security

Improved decision-making and performance: Based on ‘Engineered Labor Standards (ELS)’, the Warehouse labor planning systems can be made much more accurate and efficient compared to traditional approaches. ML-based internal route planning software can maximize the productive value of each trip, ensuring no journeys are wasted

Enhanced sustainability: Logistics companies are increasingly switching to sustainable alternatives as they yield better business productivity and improve the bottom line in the long run. Predictive analytics and other intelligent systems can help effectively manage warehouse resources and incorporate green practices to reduce energy consumption.

With the rapidly evolving consumer expectations and the disruptions caused by the current pandemic, Warehouse management is getting more complex every day. We help Logistics companies to design the right digital architecture for their warehouses resulting in higher returns from their warehouse automation investments.

To sum up, the landscape of Logistics is changing rapidly, and warehouse management is ripe for a fully digital transformation. At Persistent Systems, we help Logistics companies bring about this transformation and stay relevant in a disruptive era.

Learn more about our domain expertise and technology-driven offerings to help you turn digital challenges into opportunities.