The advent of the Industrial Internet of Things (IIoT) is being dubbed as Industry 4.0 or the 4th industrial revolution. According to a McKinsey report, this revolution is well underway, with an anticipation that the percentage of factories adopting IIoT will reach 65%-90% in advanced economies and 50%-70% in developing economies by 2025. The economic benefits are projected to be in trillions of dollars with a large percentage of those coming from improvements in Operations Optimization, Predictive Maintenance and Inventory Management.

The IIoT revolution is enabled by the advances in electronics hardware, network connectivity, data storage, analytics and cloud infrastructure. Cheaper and more powerful hardware is empowering smart sensors, wireless networks and gateways. Ability to carry large data volumes over local or remote networks for storage and processing has enabled analytics. Analytics from diverse data sets in real-time as well as offline, in turn, has opened newer business models and more efficient work-flows. Getting all these ingredients to work together is what makes the whole greater than the sum of the parts.

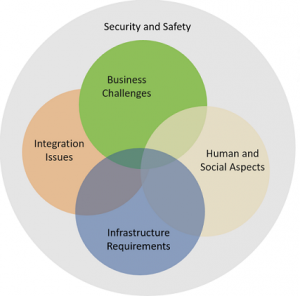

The overall IIoT adoption started gradually and seems to be accelerating now. Just like all other revolutions, the 4th industrial revolution is also not without its own resistance and challenges from Luddites who would oppose it for various reasons. There are a variety of factors behind its slower than expected adoption rate, ranging from technical to human aspects. Some of the most significant are: