Dassault Manufacturing & Operations Software

Manufacturing excellence through visibility, control and synchronization.

Manufacturing excellence requires harmony across production systems. Manufacturers need solutions that combine the virtual world of modeling and simulation with the real world of operations to connect all stakeholders and eliminate silos.

Dassault Systems DELMIA APRISO products help manufacturers to transform global production operations to sustain operational excellence. By enabling digital continuity, APRISO helps manufacturers improve visibility, synchronization and control on a global scale.

We are a world class solutions provider that can help manufacturers understand, plan, and execute their digital manufacturing journeys. We offer a blend of expertise that drives integration across the product lifecycle and supports the entire manufacturing process spanning both shop floor and top floor applications involving production, warehousing, quality, maintenance, and time-and-material. Clients choose us to tightly integrate data across legacy design and engineering, manufacturing, and operational systems with industry leading processes, software, and analytics capabilities.

Benefits

- Data easily shared across departments to improve visibility and responsiveness

- Root cause analysis for faster and more effective problem identification

- Data correlated between production, quality and maintenance supported by KPIs

- Global coordination of operations while executing locally. View, manage and control manufacturing assets as a network of capacity, to be more responsive and flexible

- Reduce global and local time-to-market, reducing cost and risk while improving quality and productivity

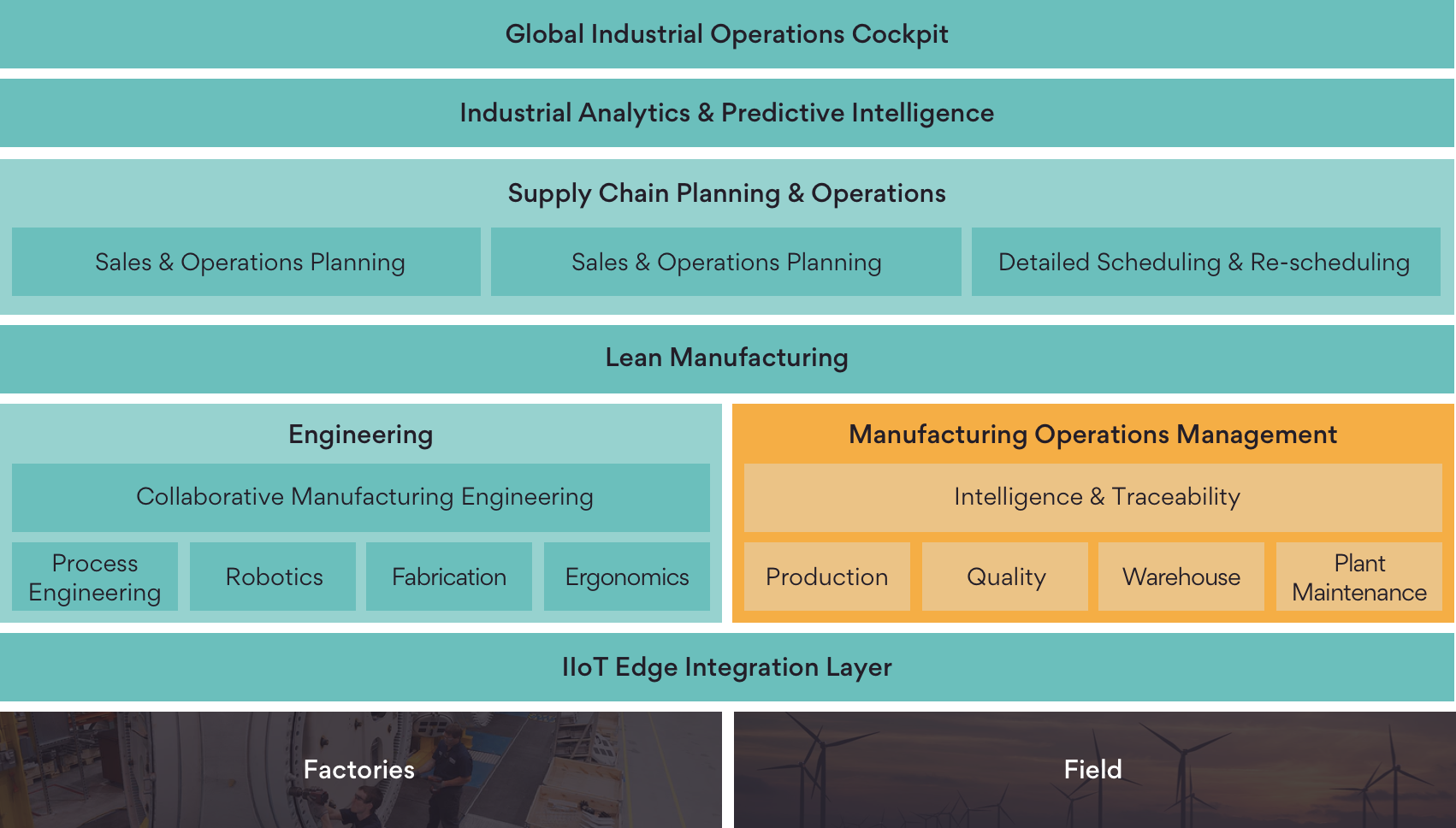

DELMIA Apriso Global Manufacturing Operations Management (MOM) – Visibility, Control and Synchronization

Why Persistent?

World Class Solutions

We help manufacturers understand, plan, and then iteratively drive their digital manufacturing journeys.

Services Leadership

We offer services expertise to tightly integrate legacy design & engineering, manufacturing, and operational systems with industry leading processes, software and analytics capabilities.

Proven Track Record

Clients choose us to create an integrated composable technology stack that drives a seamless flow of consistent, correct, and complete data from design through manufacturing operations.

News & Insights

Access our latest thought leadership and updates on Industrial.

View all Insights

Related Offerings & Solutions

-

Industrial

-

Industrial

-

CX Transformation

Contact us

(*) Asterisk denotes mandatory fields