Industrial

Powering your digital transformation with a seamless flow of data and processes from engineering to manufacturing and beyond.

Webinar Series

Attend one of our PLM and systems engineering webinars today

Persistent integrates the industrial value chain. We deliver business value by tightly integrating legacy design and engineering, manufacturing and operational systems with industry leading processes, software and analytics capabilities.

The result is an integrated technology stack that ensures a seamless flow of consistent, correct and complete data from product design and engineering to manufacturing and beyond.

Our expertise extends across the Industrial Industry

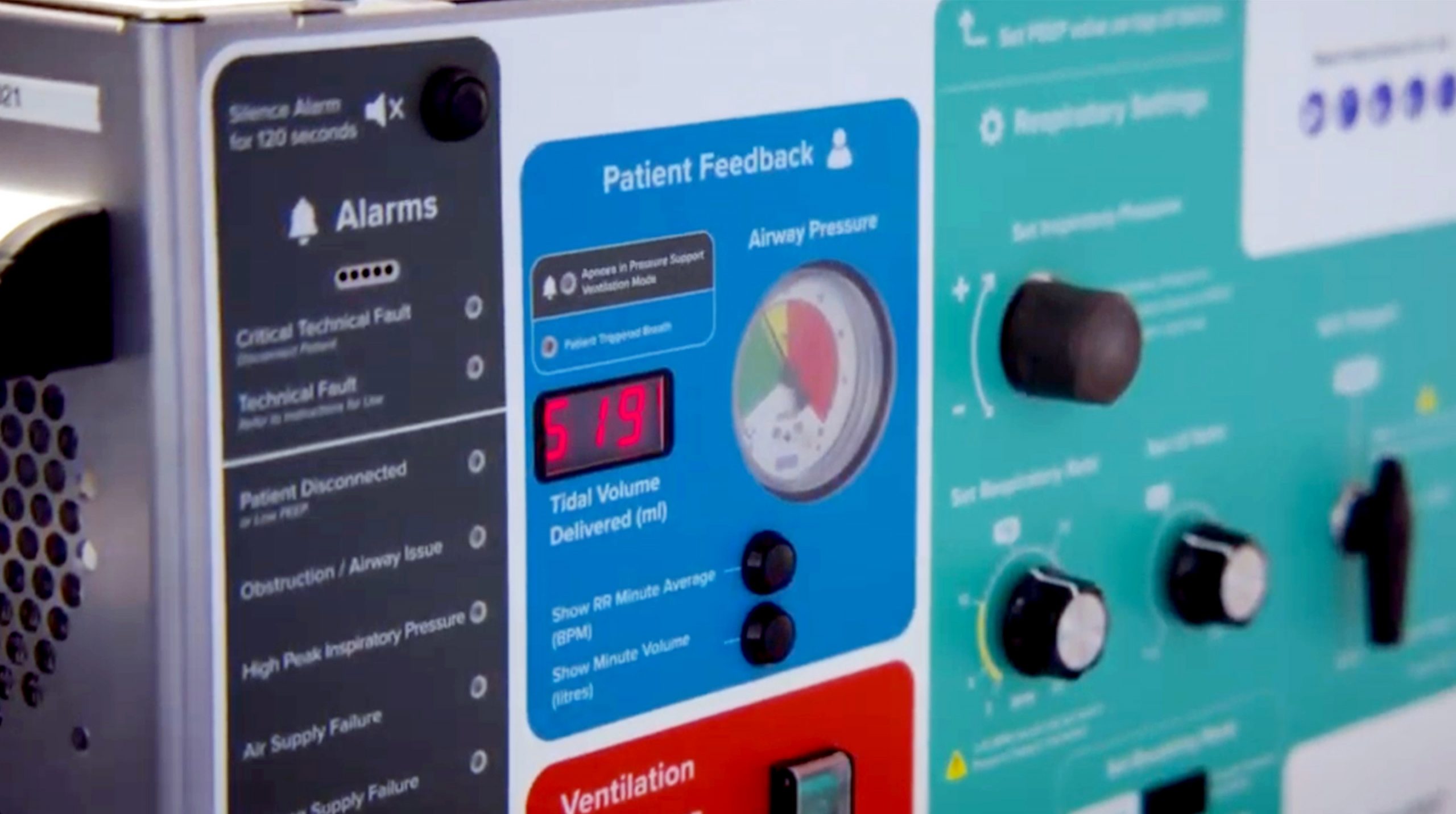

- Product Design & Engineering

- Production Manufacturing & Operations

- Customer Services & Support

Leveraging the strength of our service lines

Digital Strategy & Design

Use a Design Thinking approach to capitalize on emerging industrial trends, accelerate your Industry 4.0 transformation and open new markets.

Software Product Engineering

Software and platform engineering to build the next generation of industrial applications and integrations to streamline operations and accelerate growth.

CX Transformation

Developing and modernizing the customer experiences while bringing insights from across the industrial value chain to drive your digital transformation and capture new growth.

Cloud & Infrastructure

Imagine new business models, unlock growth, increase agility and lower cost through cloud and infrastructure modernization.

Intelligent Automation

Intelligent automation helps businesses enhance customer experience, improve employee productivity, and meet the changing needs of the industry.

Data & Analytics

Better utilize data to accelerate product innovation, streamline production and learn about your customers.

Enterprise Integration

Reduce complexity, improve organizational agility, and enhance competitive advantage through Enterprise Integration.

Application Development and Management

Develop, modernize, and maintain applications using containers, cloud and serverless technologies. Better integrate data for business decision-making and monetization by modernizing your application portfolio.

Why Persistent?

Robust Partner Ecosystem

Long-term and deep partnerships with best of breed ecosystem leaders across the industrial value chain.

Domain Leadership

Nearly three decades of experience integrating technology silos across product design and engineering, manufacturing and customer experience.

150+ Customers Success Stories

Proven track record of successfully helping customers navigate the ever-evolving industry landscape to thrive in a new, digital world.

Contact us

(*) Asterisk denotes mandatory fields